Anti-glare Coating

The AG coating (Anti-glare coating) can make the original glass reflective surface into a matte diffuse reflective surface to reduce glare, enhancing screen clarity while preserving true color representation. Even in harsh environments, this coating offers exceptional durability, making anti-glare glass an ideal choice for display equipment across a wide range of applications. Whether used indoors or outdoors, it ensures an outstanding visual experience. Hony Glass Technology can handle various surface characteristics of AG glass products, including haze and gloss levels, tailored to specific requirements.

Applications

Various displays, including mobile phones, tablets, computers, automotive displays, and industrial control displays, especially for high-brightness devices.

We offer a range of glass coating services. Please feel free to contact us to discuss your specific requirements.

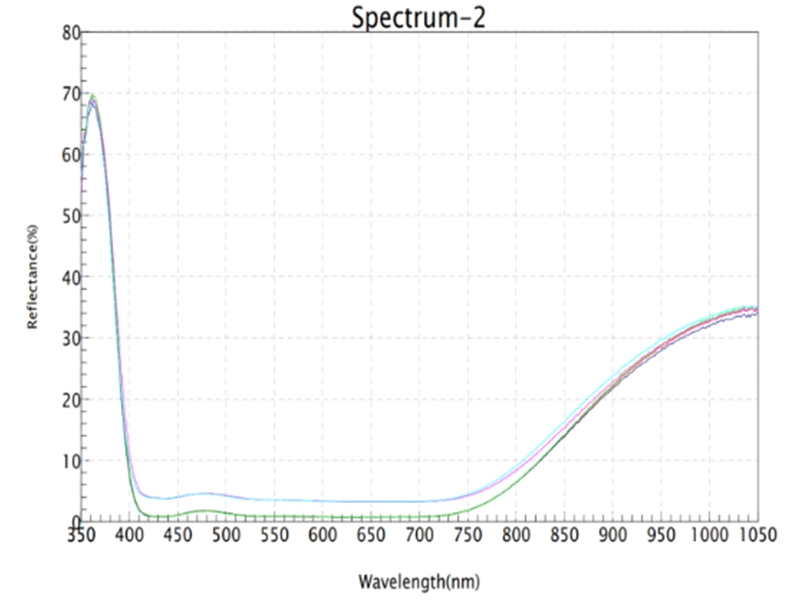

Anti-reflection Coating

The AR coating(Anti-reflection coating)glass involves applying one or more anti-reflective layers to the glass surface, reducing light reflection on the glass and thereby increasing light transmittance while minimizing visible light reflection. This allows light to penetrate the glass more effectively, enhancing visible light transmission. AR coatings can be applied to either one or both sides of the glass. Within the visible light range, AR-coated glass can achieve over 95% transmittance, and in some cases, nearly 99%, providing exceptionally high light transmission performance. Anti-reflection coated glass is commonly used in fields requiring high light transmittance and reduced glare, making display glass clearer and brighter while also reducing eye strain.

Applications

Various displays, optical equipment, and solar panels, among others.

We can flexibly select different AR coating techniques according to the specific applications and requirements of our clients. For further information, please feel free to contact us.

Anti-fingerprint Coating

The AF coating (Anti-fingerprint coating) and AS (Anti-smudge) effectively reduce the adhesion of fingerprints and other smudges on glass surfaces, keeping them clean and transparent while enhancing the aesthetic quality and user experience of products.

The Anti-fingerprint coatings form a hydrophobic and oleophobic protective layer on the glass surface, significantly lowering surface tension to repel water, oil, and dust. This makes cleaning more convenient and effortless. In addition to minimizing maintenance time and costs, these technologies extend the product’s lifespan, making them ideal for devices requiring frequent contact or cleaning.

Applications

Smartphones, tablets, touch displays and automotive screens.

We provide tailored solutions and professional recommendations based on specific customer applications and requirements. For more information, please feel free to contact us.

Anti-bacterial Coating

Our glass anti-bacterial coating technology has been widely applied in medical and public touchscreen applications. For more information, please feel free to contact us.

ITO Coating

A transparent conductive layer coated on the surface of glass, ITO coating provides both electrical conductivity and high transparency. It is widely used in various touch display panels and electrochromic devices. If you have any requirements for glass ITO coating, please feel free to contact us.

Photocatalyst Coating

Photocatalytic Glass Coating is a surface treatment technology designed for glass. This technique involves the uniform application of photocatalytic materials, such as titanium dioxide, onto the glass surface, enabling self-cleaning and antibacterial properties. The photocatalyst reacts to ultraviolet light, effectively decomposing organic dirt and bacteria while preventing their growth, thus ensuring the glass remains clean and hygienic. Typically non-toxic, photocatalytic materials work under light conditions, making them environmentally friendly and compatible with modern sustainable development principles.

Moreover, the photocatalytic coating does not compromise the light transmittance of the glass, preserving excellent optical performance and ensuring bright indoor lighting without affecting visual clarity. The photocatalytic glass coating technology developed has found extensive applications in medical facilities, commercial environments, and residential settings, significantly reducing the presence of pathogens and harmful substances, thereby providing customers with a safer and more comfortable living and working atmosphere.

Applications

Automotive, construction, electronic products, public spaces, and medical equipment, among others.